We have a monitoring software that keeps track of our client’s products providing critical on time information. We are able to track the stage were the product is at, raw material used, employee participation, machinery involved, etc. This helps us increase productivity and assure a quality product.

By integrating every process in our shop into one system we are able to identify our week points and focus our efforts into that area that needs improvement. In addition our customers have the confidence in knowing exactly what went into their product.

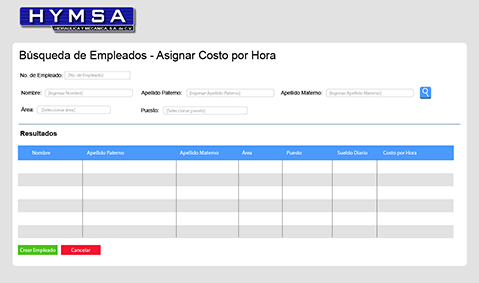

Formed with a complete cycle registry and monitoring location, physical and logical (by assigning a work order), of tools, raw materials, machines and human resources which allow our supervisors to know at any time what is the status of the product: who is working on it and what he´s working with.

We also manage our inventory stock since it is an utmost importance the knowledge of the materials to always have the minimum level of inventory. This is obtained by a day-to-day update of the materials, tools, and consumables needed on each of the production process.